Product Introduction

Vertical shaft sand making machine is a kind of straight through adjustable fine crushing equipment developed by our company according to the market demand and on the based on high- quality fine crushing equipmentall over the wold. The equipment can be widely used in cement, refractory, building materialsand artificial sand making industries, for the fine crushing operation of limestone, pebble,dolomite, blast furnace slag, coal mine stone,refractory and other medium hard stones, It is especially suitable for making and crushing artificial sand and stone for highway.

Performance Features

1.The structure is simple and reasonable, the running cost islow, and the wear is small,

2.High breaking rate and energy saving

3.It has the function of fine crushing and coarse grinding.

4. Affected by the moisture content of the material, themoisture content can reach 8%.

5. The working noise is less than 75 decibels (db level), and the dust pollution is less.

6, Suitable for crushing medium and hard materials,

7,The product into a cube, bulk density, iron pollution isminimal

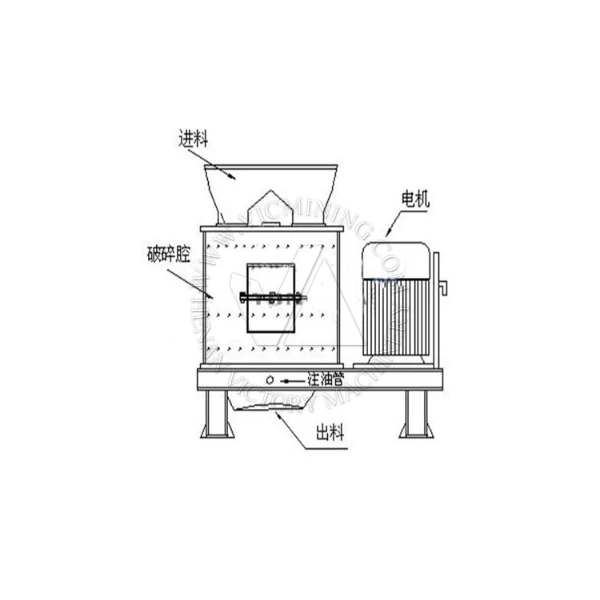

Working principle

The materials fall vertically into the high-speed rotating impeller from the upper part of the machine. Under the action of high-speed centrifugal force, they ollide and crush with thematerials distributed around the impeller in the form of umbrella. After the materials collide with each other, they will collide and rub with each other for many times between the impeller and the shell, and then they will be discharged directly from the lower part, forming a closed circuit and multiple times of circulation The ring is controlled by the scre ening equipmentto reach the required particle size of the finished product Mainuses Vertical shaft sand making machine is suitable for crushing limestone, clinker, coal and other ores in building materials,mining, metallurgy and che mical industries. Its compressive strength is not more than 140 MPa, and its humidity is not more than 15%.

Product Parameters

| Model |

Feed partical

(mm)

|

Discharge Granularity

(r/min)

|

Processing capacity (t/h)

|

Motor Power

(kw) |

Spindle Speed

(r/min)

|

Dimensions (mm)

|

| PFL-800 |

100 |

0-5 |

10-20 |

22 |

934 |

2100*1200*1700 |

| PFL-1000 |

120 |

0-5 |

20-40 |

45-55 |

769 |

2600*1400*1900 |

| PFL-1250 |

150 |

0-5 |

40-70 |

75 |

530 |

2800*1600*2100 |

| PFL-1500 |

180 |

0-5 |

70-100 |

132 |

495 |

3100*1900*2200 |

| PFL-1750 |

200 |

0-5 |

130-190 |

160 |

424 |

3710*2360*2390 |

| PFL-2000 |

220 |

0-5 |

200-260 |

185 |

370 |

4100*2660*2620

|